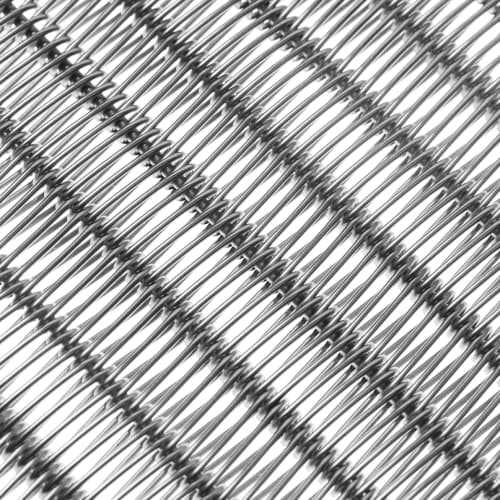

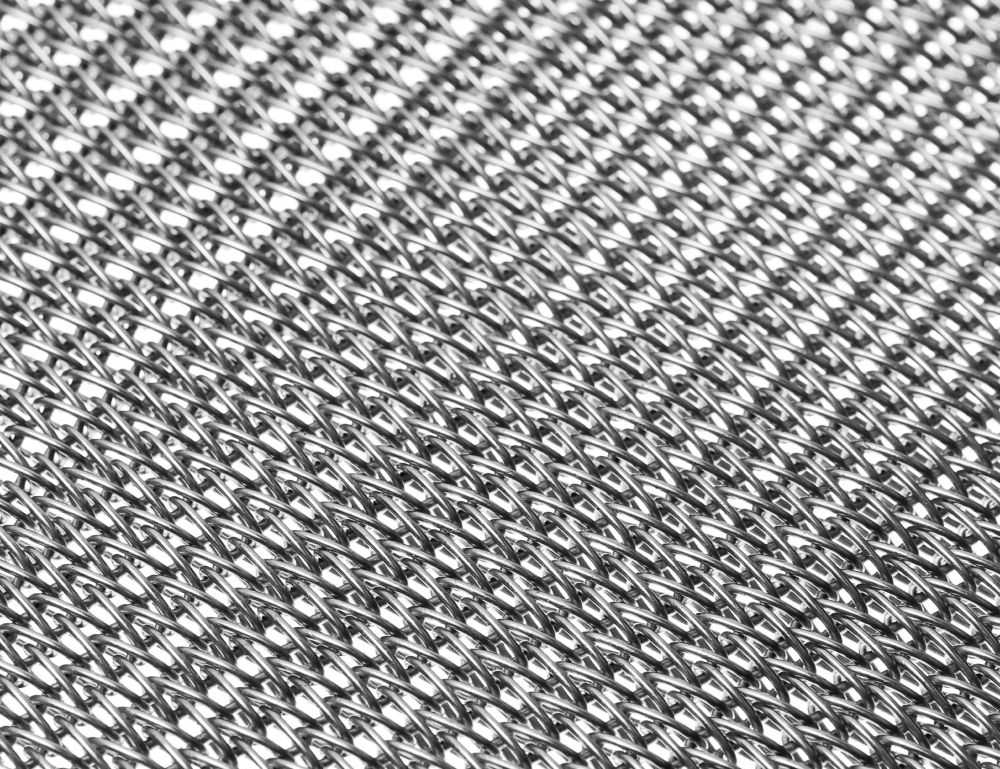

TBC

Tbc belt has left and right spirals connected by straight cross rods. The spirals are attached under tension ( low coil pitch ) to ensure its stability and dense surface structure. Cross rods are bended and attached adjacent rods. This belt type mainly preferred in wide baking lines due to its excellent stability performance.

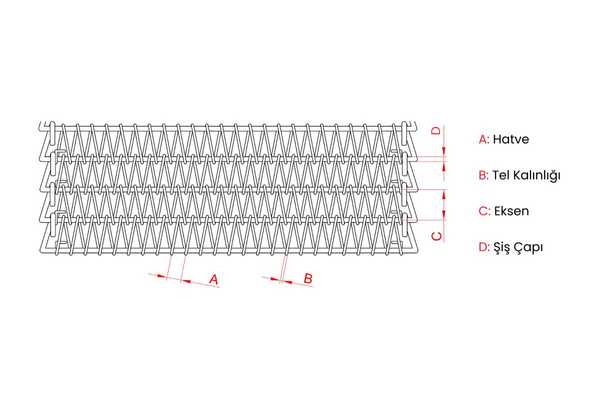

TBC - Technical Drawing (Woven Conveyor Belt)

TBC - Dimensions: (Woven Conveyor Belt)

| B: Wire Diameter | D: Rod Diameter | A: Coil Pitch | C: Rod Pitch |

| 1mm | 2 2,5 | 2 3 | 12,7 16,5 |

| 1,2mm | 2 2,5 | 2 3 4 | 12,7 16,5 19 21 |

| 1,5mm | 2 2,5 | 3 5 8 10 20 | 12,7 16,5 18 21 |

| 2mm | 2,5 3 | 6 9 11 15 | 16,5 19 21 30 |

| 2,5mm | 3 4 | 6 8 | 21 30 |

Types: Woven Conveyor Belt

TBA1

TBA-1 belt has right and left-hand spirals connected by bended (crimped) cross rods. These alternating right and left-hand wire spirals allow the belt to be well-balanced and to maintain its straightness and have perfect strenght-weight ratio.

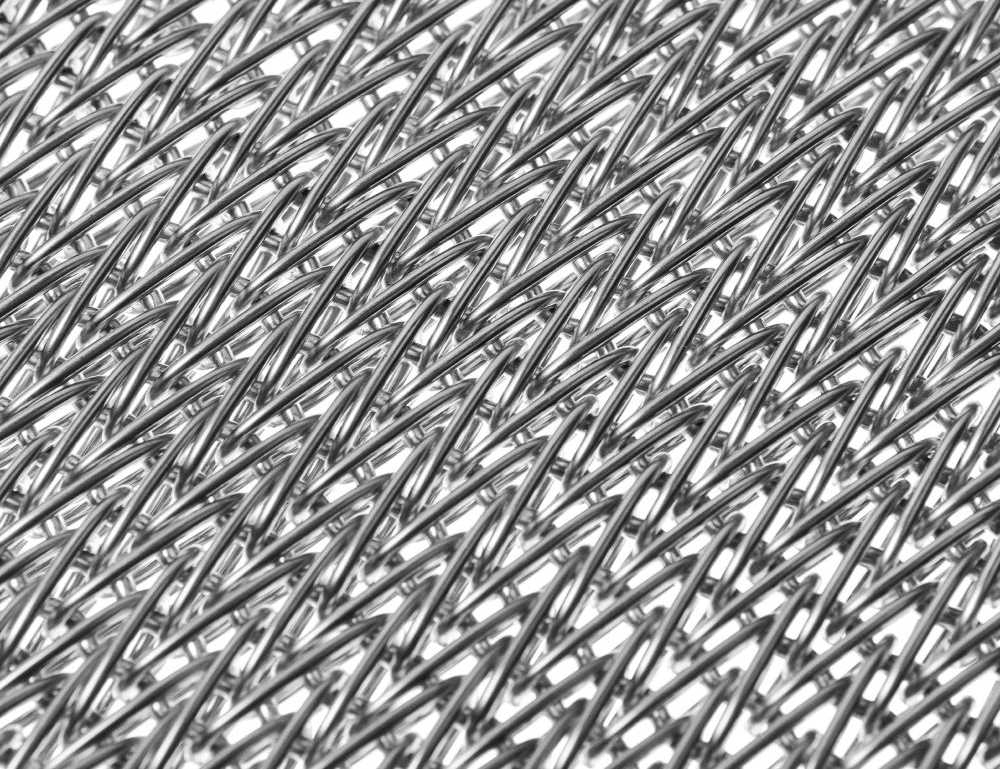

TBA2

TBA-2 belt has right and left-hand spirals ( 2 rods in 1 spiral ) fitted closely for a smooth, dense weave. It is excellent for conveying small products while allowing air flow for baking, drying&cooling or roasting purposes.

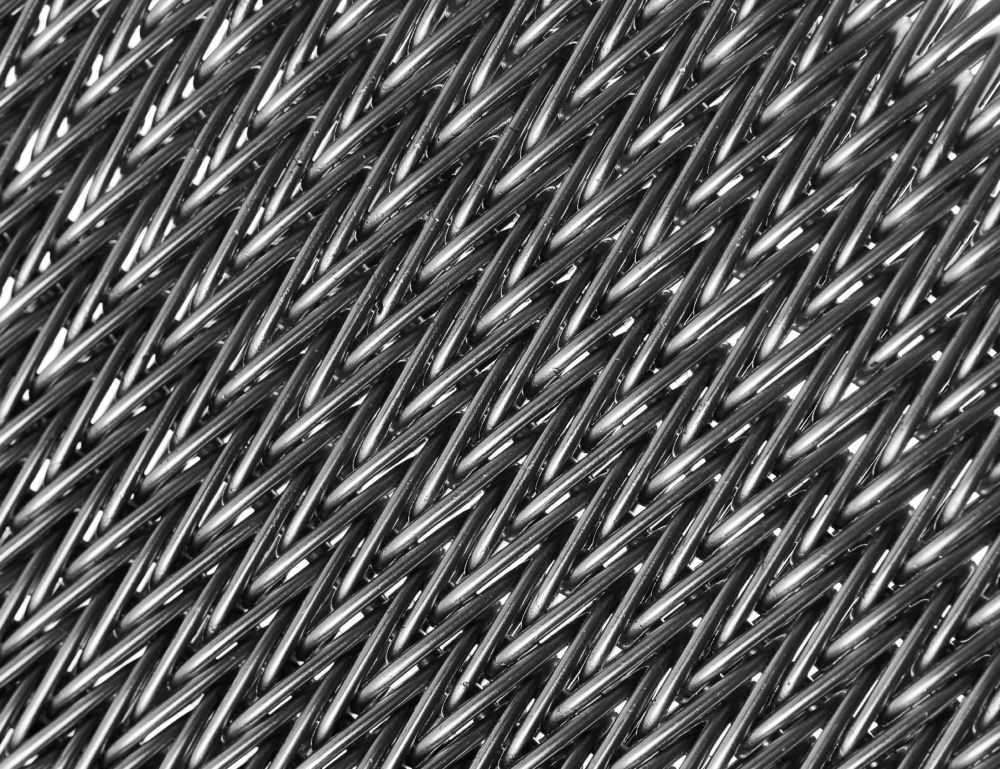

TBA3

TBA-3 belt has right and left-hand spirals ( 3 rods in 1 spiral ) fitted closely for a smooth, dense weave. It is excellent for conveying very fine or small products. This belt type model provides a closed mesh surface that is extremely strong, flat and supportive.

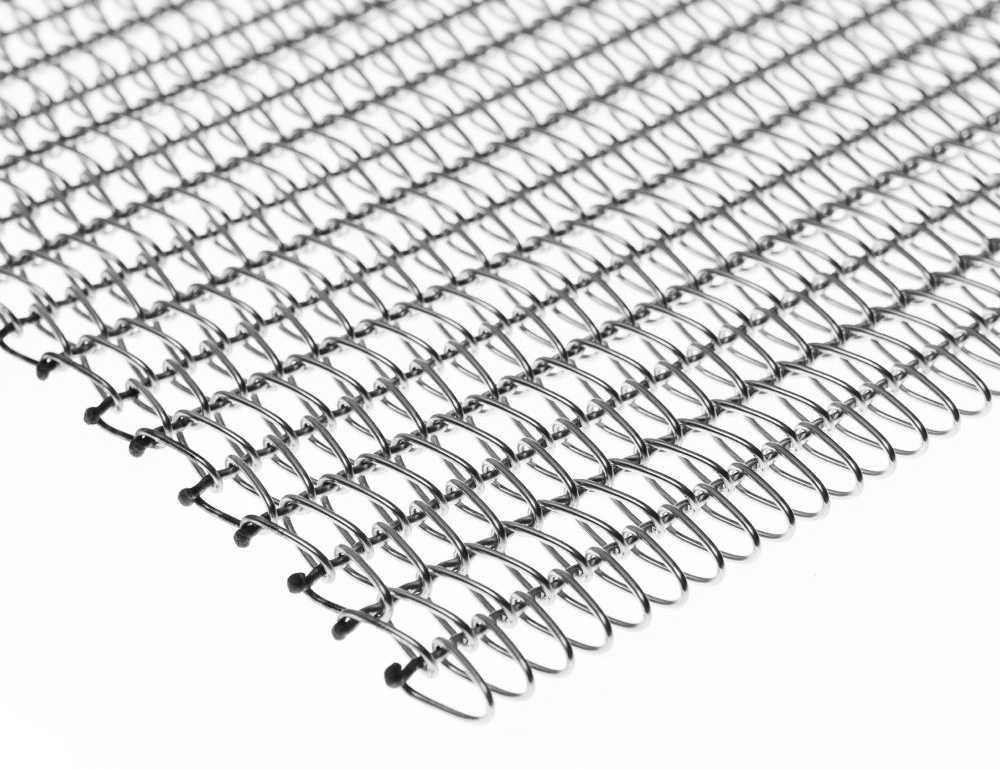

TBB

Tbb belts consists of only left and right spirals twisted into one another. The ends of the spirals are either welded or bended.

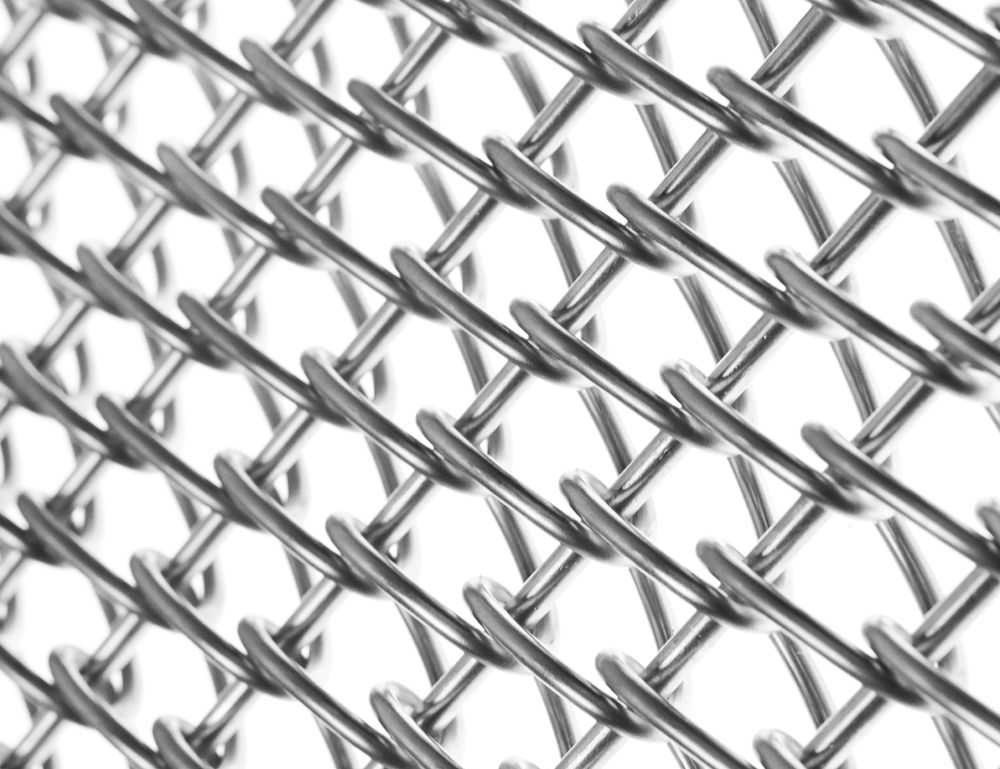

TBD1

TBD-1 belt has linked spirals, connected by straight cross rods. This belt is used mainly in continuous ovens, for heat treatment of products or for sintering and brazing processes.

TBD3

TBD-3 belt has right-and left-hand spirals ( 3 rods in 1 spiral ) fitted closely together for a smooth, dense weave. It is excellent for conveying very fine or small products. This belt type model provides a closed mesh surface that is extremely strong, flat and supportive. Unlike TBA-3 , it uses straight cross rods to ensure long durability in high temparature conditions.