Features

Woven conveyor belts show a variety of sizes, models and materials according to the size, type and working environment of the product it carries. Packaging, transfer, transportation, annealing, heat treatment, cooking, frying, drying and cooling are among the preferred areas in the use of conveyor belt. It is varied according to the number of spirals used on an axis and whether the rod passing through the spiral is flat or bended ( crimped ), as well as special edge endings suitable for the purpose of the line. T-Bant helps the customer choose the right type of conveyor belt and material according to working conditions, shape, size and weight of the product to be transported.

Types: Woven Conveyor Belt

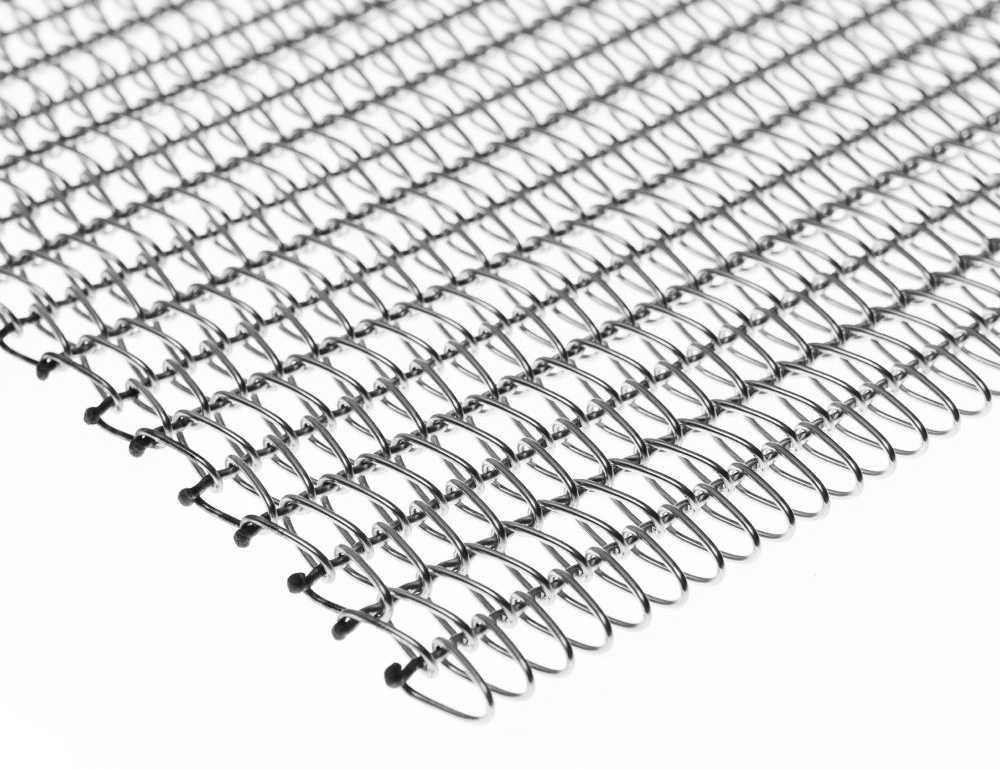

TBA1

TBA-1 belt has right and left-hand spirals connected by bended (crimped) cross rods. These alternating right and left-hand wire spirals allow the belt to be well-balanced and to maintain its straightness and have perfect strenght-weight ratio.

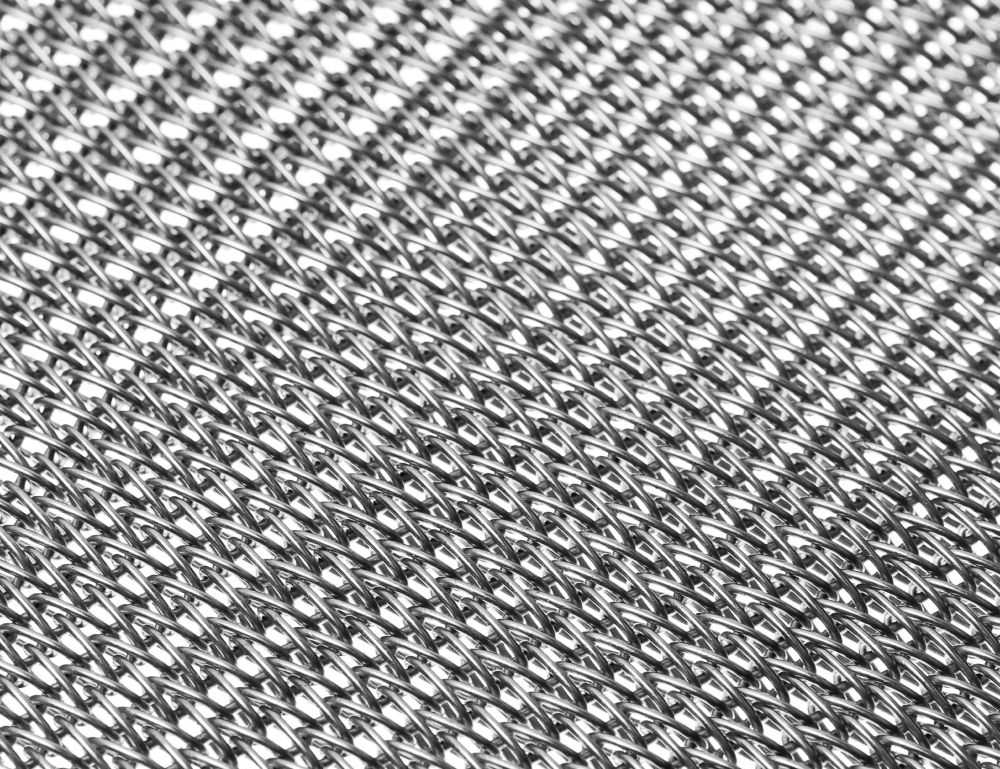

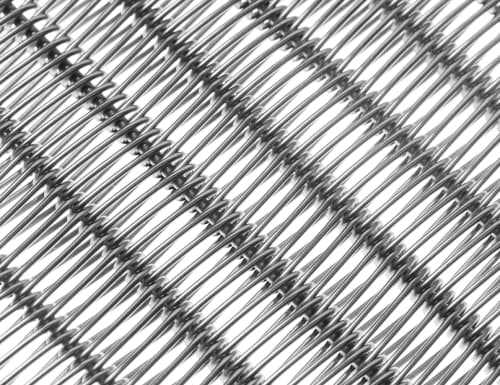

TBA2

TBA-2 belt has right and left-hand spirals ( 2 rods in 1 spiral ) fitted closely for a smooth, dense weave. It is excellent for conveying small products while allowing air flow for baking, drying&cooling or roasting purposes.

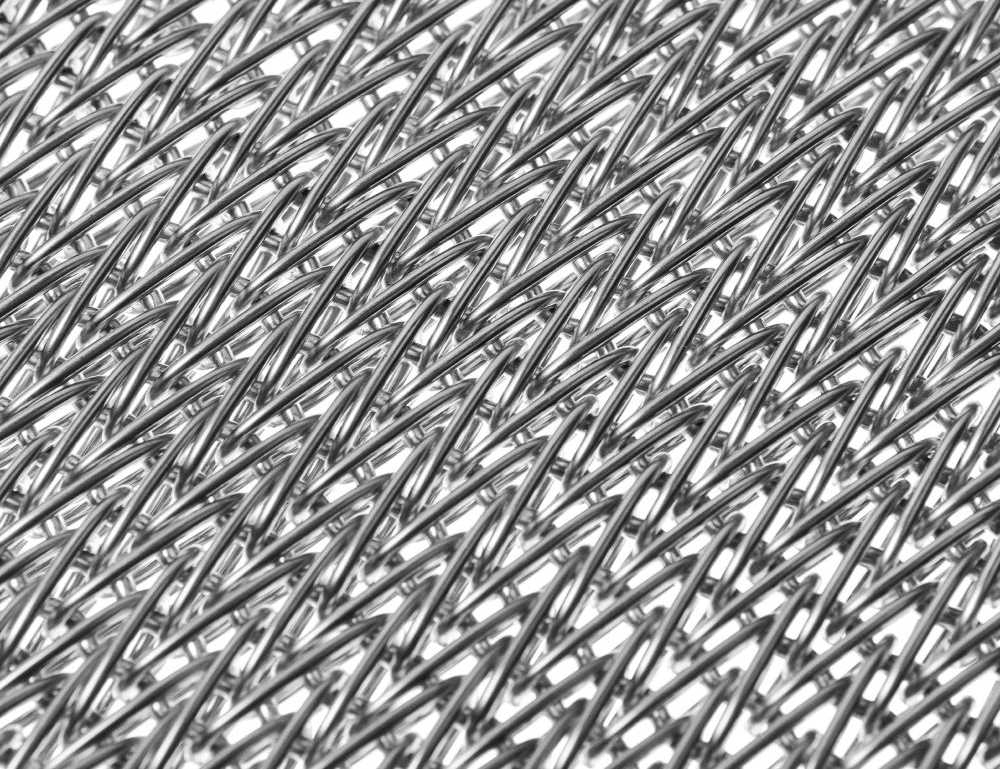

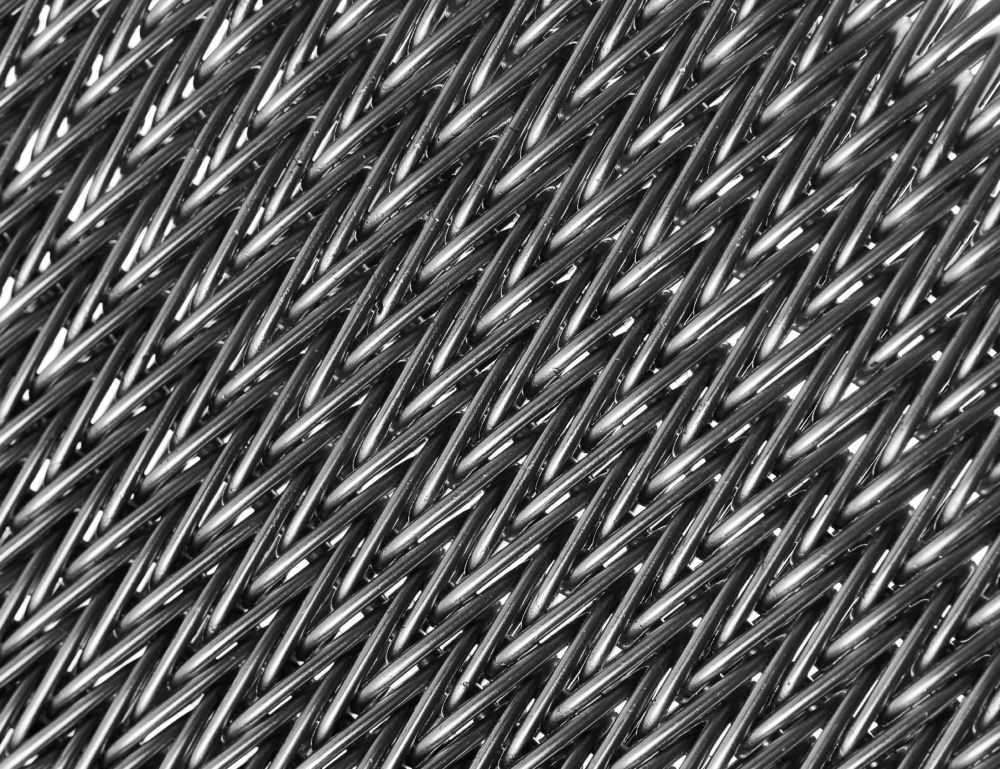

TBA3

TBA-3 belt has right and left-hand spirals ( 3 rods in 1 spiral ) fitted closely for a smooth, dense weave. It is excellent for conveying very fine or small products. This belt type model provides a closed mesh surface that is extremely strong, flat and supportive.

TBB

Tbb belts consists of only left and right spirals twisted into one another. The ends of the spirals are either welded or bended.

TBC

Tbc belt has left and right spirals connected by straight cross rods. The spirals are attached under tension ( low coil pitch ) to ensure its stability and dense surface structure. Cross rods are bended and attached adjacent rods. This belt type mainly preferred in wide baking lines due to its excellent stability performance.

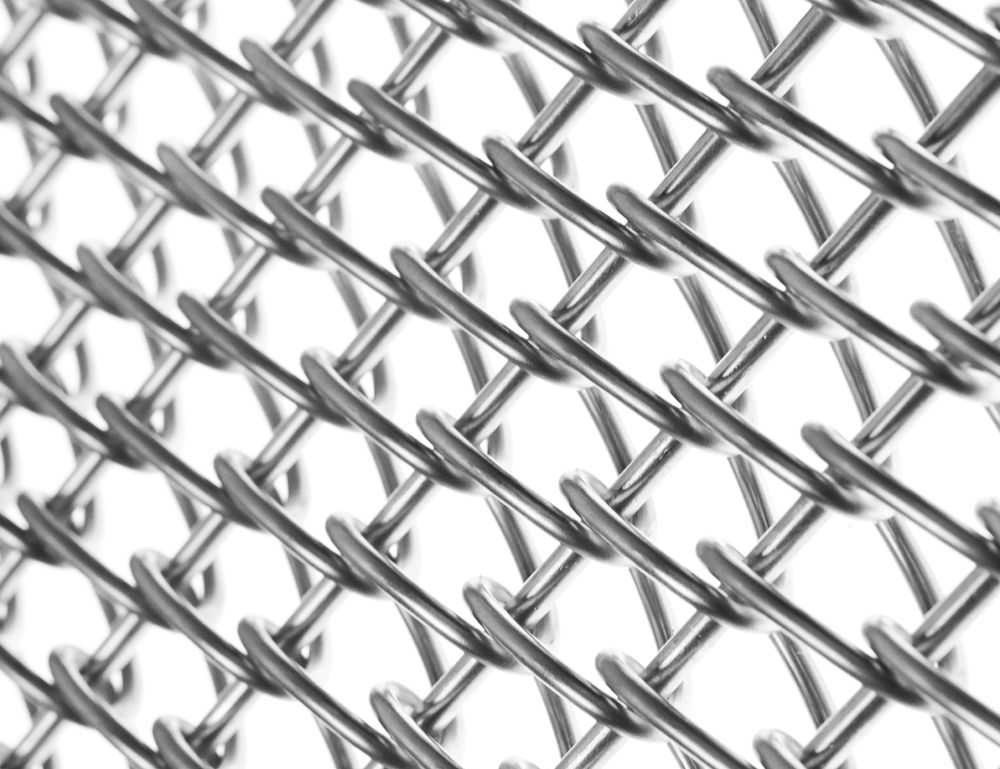

TBD1

TBD-1 belt has linked spirals, connected by straight cross rods. This belt is used mainly in continuous ovens, for heat treatment of products or for sintering and brazing processes.

TBD3

TBD-3 belt has right-and left-hand spirals ( 3 rods in 1 spiral ) fitted closely together for a smooth, dense weave. It is excellent for conveying very fine or small products. This belt type model provides a closed mesh surface that is extremely strong, flat and supportive. Unlike TBA-3 , it uses straight cross rods to ensure long durability in high temparature conditions.

Characteristics

DIMENSIONS

MATERIALS

AISI 304:Temperature up to 450°C

AISI 310:310S- 314 -- Temperatures up to 1200°C

AISI 316:5 Resistance to heat up to 550°C, salt and acid (corrosion) resistance Galvanized and copper coated, 24MnB4 materials: → No corrosion resistance. Heat up to 200- 250°C Since all materials are bright and have a smooth surface, they do not stick to the product during contact.

USAGE

- Biscuit, crackers, cake baking and cooling line

- All kinds of product transfer and automation line

- Meat, chicken and fish cooking, frying, paneling, cooling line

- Shrink (packaging) line

- Annealing and heat treatment conveyor belts (connection equipment, automotive parts

- Wafer, pita, pizza cooking oven Architectural mesh