Features

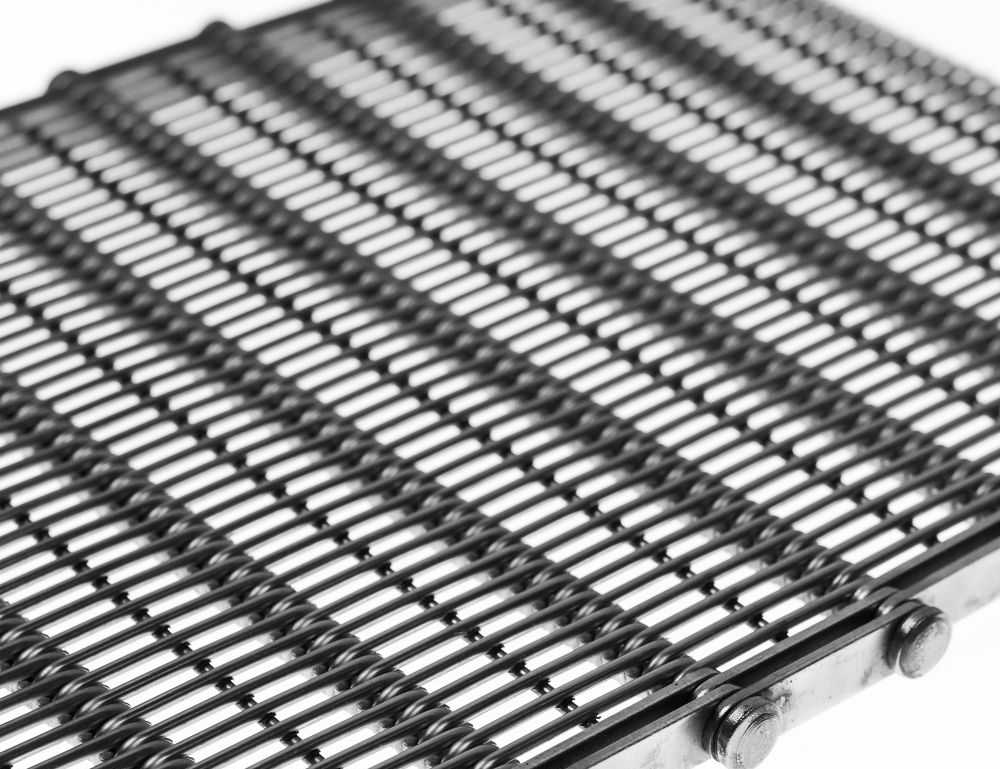

Eye-link conveyor belts are produced by passing thicker straight rods between wire loops ( eyelinks ) . Usually, the eye-links are reinforced by centering another rod that goes along the length of each other (TB-EP). This belt is excellent when durability, flat carrying floor and precision are desired. This heavy carrying belt is preferred by the glass, bottle and textile sectors. The biggest advantage is that it is very durable and long-lasting. There are also alternative models where bushings or springs are placed between the eye-links. (TB-F) In this conveyor belt model, higher permeability is achieved thanks to the bushes and springs placed between them; preferred for lighter and faster lines.

Types: Eye- Link Conveyor Belt

TBE

This conveyor belt model is formed by placing wire loops (eye-links) without gaps between them. The space between the eye-links is the same as the thickness of the wire. It can be preferred in cases where the amount of space in the conveyor belt is not needed (air & luquid flow rate) and the material carried is poured heavy and/or from a certain height.

TBEP

Wire is welded between the eye-links to make it more stable and durable. Thanks to this welding, the distance between the eye-links can be increased. It is a lighter model. But it is not suitable for heavy loads and harsh conditions. The number of rods to be tack welded onto eye-links can be one or two

TBF

This conveyor belt model is produced by placing a bush or spring between the eye-links. With these bush and spring placement, the desired amount of space and permeability are provided. If the bushing is placed between the eye-links, the conveyor belt becomes heavier, stable and resistant to vertical high forces. If the spring is placed, the conveyor belt becomes more resistant to horizontal forces and shocks. Also it is a lighter conveyor belt model than others.

Characteristics

DIMENSIONS

MATERIALS

AISI 302/304: It is used in the temperature range of -50°C - +250°C in processes that require normal corrosion resistance and temperature. It is preferred in areas such as meat-fish processing, wool & fiber lines, and food processing lines.

AISI 316: It is used in processes that require high corrosion resistance due to salty or acidic environment. Salt coating lines, fruit processing lines, fertilizer processing lines are preferred in such areas.

Carbon Steel Material (AISI 1040, AISI 1045, AISI 1050):This material is used when little to no corrosion resistance is required. temperature range of -15°C to +85°C.

USAGE

- Packaging and canning line

- Cooking, cooling and freezing line

- Washing and drying line

- Fermentation line

- Frying and coating line

- General heavy load transport lines